The method - invert the lathe beds and set them up end to end, align them with straight edge, mix epoxy and apply coating to the mounting plates, lower the box section with greased dangling mounting bolts into position and let time and gravity do the work, clean excess epoxy before it sets on surface table or kitchen worktop. When the epoxy has cured nip up the mounting bolts. Some locating dowels in each mounting plate would not go amiss. With your strong friend turn the assy. over and install in req'd location. The beds are aligned as accurately now as they were inverted."

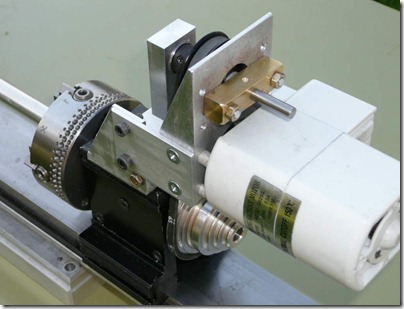

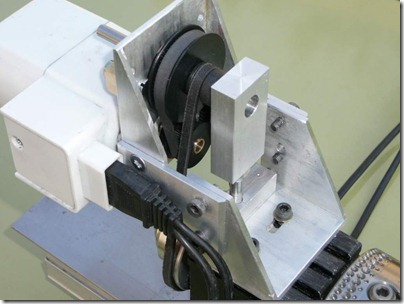

"My 'bookends lathe' constructed to work on cylinders and barrels, picture is posed, the gap arrangement is forward planning just in case I have some large diam., work to swing, no riser blocks are needed for the head and tail stock."

"My bookend lathe has the sewing machine motor drive revised, it could really do with halving the speed again but it can handle crowning and breech work on barrels and cleaning up the ends of compression cylinders. Pics of that show another use for my never ending supply of 2 1/2" ally channel and left over pulleys from my Thread Box project."

Thanks Monty!

Beautiful.

ReplyDelete