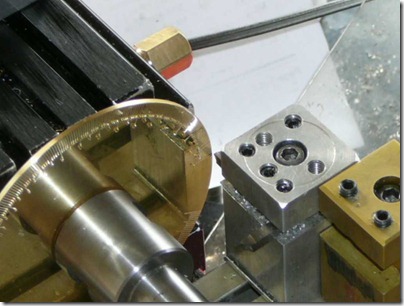

I have also just noticed that the bracket could be left in place when the tailstock is repositioned normally, and that it might be beneficial if the ram works against the brass edge then some load is taken off the air gap and is transferred to the clamping bolt assy.? (I did drill the hole first then file the edge until I had a running fit with no rocking evident.)

Monday, June 6, 2011

Monty Remon’s Notes on His Improved Tailstock Linkage Bracket

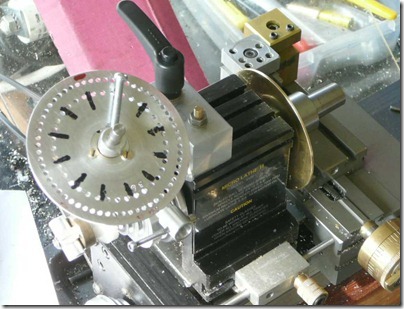

Monty Remon’s Latest Indexing Attachment For The Taig Lathe.

Well you suggested fitting a worm /gear assy., to my headstock spindle to do some indexing work, so that is where I started from.

My attempts to come up with a solution that involved a quick flip down, engage gear and brake assy., gizmo using brackets and plates eluded me for hours but as usually happens I got inspiration from elsewhere in the form of a large hex key on my bench, so I came at the problem from a different direction, 90 degs in fact! What started out with a hex key now has more resemblance to a box spanner/tommy bar. I will try and put the pics in some sort of order with a few words of explanation of how I got 'tooled up' starting with a pic of my hex key and first experiments with mounting clamps and "T" bar arrangements.

A picture of all the removable components clockwise from top left - eccentric 1/4" location collar, 1/4" spacer, 1/2" eccentric brake mounting, brake/pinch bolt, 3/8" spacer, mounting arm with worm shaft bearing assy., the worm shaft and worm, seating collar for division plate, division plate/carrier/clamping bolt assy., thrust washer, shaft location collar, indexing arm assy., and securing screw/washer for the arm. What NO sector arms!!!!!A few notes on some of the above components, the spacers I managed to make out of an old syringe with an id of .75" they set things up axially to align the brake and worm when installing the system with my pulley mounted worm gear. The locating collar and the brake mount could be made from 1" diam bar and bored out eccentrically to match the main support arm, but I was lucky having some 1.25" x.25" ally tube that could be offset 1/16 in the chuck turned eccentrically to leave a 1/4" flange on the outside for the brake seating. The collar needs a small drilling for a tommy bar in order to rotate it and set the brake arm to spindle centers distance. The locating collar only needs drilling and tapping for a grub screw. The brake assy, is cut out from 1/4" ally sheet with one hole to clear the 1" diam., adjusting eccentric and at 1.666" ctrs., the other hole is 1.666" diam., (spooky!) to clear the plain portion of the Taig pulley. A saw cut joins the two holes and the edges were thinned down to 1/8" to give it a little spring. A small grub screw is fitted in the top, this is only nipped up once the eccentric is correctly aligned and the spindle/pulley runs free in the brake. The whole brake assy., should be free to swing on the arm. The pinch bolt is a 4mm hex head bolt, within an ally sleeve, the sleeve end is recessed at 7.5mm diam., and the bolt head was pressed into this using a vice.

The main support arm is .75" diam., and should have been 3.5" long (OOPS), the extra .25" I misplaced from the end was an alternative location for the brake assy., to be used when a gear/brake drum was mounted directly on the spindle. The scrap box supplied the tube but I had to fit a plug in the end but this plug would not be needed if the bar is solid. The arm is cross drilled and reamed out to .5 to accept the bearing tube.The worm shaft tube is .5" CDS with 6mm brass bushes glued in the ends, a .25" reamer is fed in after fitting. The bearing tube is located by a screw down the center of the support arm, this screw is not locked down and in tension, but is tightened by torque only (the head is loose). A tapping hole was drilled through both components (only one wall was needed), then a No 2 tap fed in slowly checking the fit of the bolt occasionally until the bolt end can just be seen protruding through the tube wall, when the thread was tight at the tube/arm interface I called it located. Several holes could be drilled and tapped to cater for different worm/gear combination's, and with an asymmetric arm location too a quick 180 gives a degree of adjustment.

The support collar for the division plate should really have been made from brass but the scrap box was lacking. The division plate carrier is ally, bored out to 1/2" to fit the bearing tube, the flange is .75" (Taig spindle fit). The div., plates are fixed to the carrier with 3 c/s screws @120 degs and .75" diam. The extended locking arm is brass and the knob on the end needs to be positioned so that it clears the div., disc radially but its edge is at least level with the the disc surface as it also functions as a datum/pointer. The sector arm is brass, slotted, standard issue but I've hung a clear pointer at one end for reading the protractor and a detent pin at the other.

The detent pin assy., was inspired by one of your emails Nick. The ratcheting pen top mechanism moldings and the spring were kept and a pin was turned from brass to replace the ink cartridge. The ally housing slowed me down as I had to set up my pull through threading system and cut an internal pen thread. Once I realized a spring needs room to function I was home and dry. The ribbed ally (brass later) sleeve permits frantic action without friction burns. The whole thing works a treat.

•The two pics, end on and side on saved me the trouble of drawing a quick sketch to show the layout.

•and a third...another I found that makes me think I should be off Tahiti "Two points to stbd., Mr. Christian"!

The mounting clamp on the headstock is 1"x1"x2" ally with a split .75" diam., hole. No registration plate was req'd, just holes at the corners fitted with screws and large washers. I used a ratcheting lever on the clamping slot, initially I had thoughts of slackening this off and jumping teeth while counting in 12s! but that is slower than winding the handle. As can be seen I used delrin gears from HPC, and the fact that I had some ready made components to mount the gear on the end of the pulley lead me to prepare the clamping face with some cut grooves.

The headstock was reversed and one of my older alclad div., plates was mounted on the spindle and my hex pin pressed into action, a bit mounted in the tool post on the cross slide and set to 7 thou did a splendid job, better than knurling I have examples of. While I had that system set up I reversed the head stock and mounted the dividing head assy., and clamped a previously prepared brass disc blank on the spindle for marking a protractor plate as per Tony Jeffree's article. I set the cut depth to 3 thou, many hours later and a quick polishing the markings were still crisp.

Preparing div., disc blanks. Brass sheet bored out to fit Taig spindle, soon to be mounted and turned to diam..

Installing the dividing head assy., on the head stock. Slide the arm into the mounting clamp, the brake will hang down and slip over the pulley assuming the eccentric has been adjusted correctly, when the location collar abuts the mounting tighten the clamp and check the spindle is free, then release and rotate the arm until the worm engages the gear and tighten the clamp on the arm again.

Mounted

The rotating division plate is my way of not making sector arms. To use it, release the div., plate clamp (datum) and detent pin, advance the disc assy., past the sector arm in DOR by the req'd number of degs/sectors, clamp it. Now wind forward to 'zero' and then the full number of turns as req'd.

Throughout the development work on this dividing head I was constantly referring to Tony Jeffree's two designs and one of the ways I can see I have to go is to use my spare headstock with the legs removed to enable me to mount the device elsewhere on my lathe. Another idea I must follow up is T.J's 120 hole div., plate working to 1/10 deg., but I calculated a disc of 4 1/2" diam., to give 120 holes surrounded by metal, not 3". However I like the idea so much I have found a solution. One set of 60 holes (evens) which could be at 2 1/4" diam., and then another set of 60 holes (odds) offset 3 degs., at a slightly larger diam.. I had better get drilling. It is just his 'egg sucking' I have to try now.