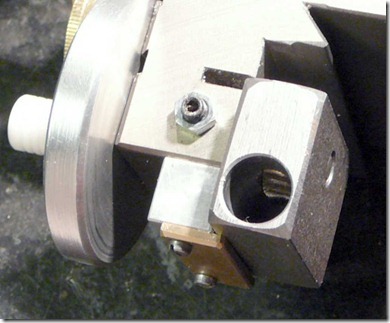

I rarely use the drilling tail stock with the cross slide in place, so it's a case of swapping one component for the other. Anyone with the new power feed lathe will be aware of the problems of sliding the carriage back on the bed with the lead screw flailing about. For those that don't the lead screw is driven by the g/box via a spring and it is really floppy, its end locates in a pivoting block on the carriage assy., trying to line up these components several times per job is a pain. My solution to the problem was to limit the angular movement of the block to a few degrees by bolting a plate and a bit of 1/2x1/2 to the bottom of the carriage. I turned a bullet shaped guide out of brass to fit the end of the lead screw. How do you machine the end of 12 inches of 1/2" diam., lead screw in a Taig lathe? It will not go through the spindle and it is too long to mount in the chuck. I attacked the problem from a different direction. The drilling tail stock just happens to be great for clamping 1/2" lead screws if you remove the ram and lever first. A mill was colleted (?) and drill and tap was chucked in the head stock end and the work fed into these by sliding the tail stock in by hand. With the guide fitted the assy., was reconnected to the gear box and now the carriage can be slid onto the bed and the lead screw located blind with the minimum of fumbling. The other problem with the spring coupling is the lack of control with about 3/16" of axial play in the lead screw it feels like you are machining rubber! The way I tightened things up was to put a groove in the brass guide fitted on the end of the lead screw and make a sliding bolt assy., to engage in this to restrict axial movement. The whole thing clamps in the dovetails on the back of the bed in the same manner as the g/box mounting. It now feels as responsive as the older rack and pinion system.

Sunday, March 6, 2011

Monty Remon’s Power Feed Leadscrew Mod

Labels:

Monty Remon

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment