Mike Wooten sent these pictures of his lathe and custom motor mount.

Thursday, May 22, 2014

Karl Harnish's New Handle For His Taig Tailstock

“My Taig is on a large board that just sits on my workbench and it has occasionally moved if I put too much pressure on the original handle, so I thought I would try for a handle that will allow a push and a pull at the same time to see if that would help. (I guess I could learn how to sharpen my drill bits, or at least buy new ones.)

I started with an eighth by half mild steel and duplicated the holes from the original steel, then cut the new piece to length, leaving about 2.5 to 3 inches beyond each hole.

I put a piece of 1 inch wooden dowel rod in the milling attachment/vice, and using an eighth inch Dremel burr in the collet, I cut a blind slot about 3/4 inch deep, as long as the cross slide travel would allow. My idea was to try to get the center of the steel in about the center of the wood. Once the slots were cut, I cut off the dowel at one edge of the slot and cut the other end leaving a 6 and a half inch piece and a 5 and a half piece. A little time on the sanding wheel eased the edges Again, using the milling attachment and vice, I drilled and counter sank the holes in the wood, more or less an inch apart, slightly beyond the slot to allow for the 8-32 x 1/2 socket flat head screws to bottom out in my counter sunk holes. Then I fit the steel into the slot, and tapped it tight to the bottom and end of the slot and marked where I needed to drill the holes in the steel. The steel was then drilled and tapped for 8-32 machine screws. I didn't see much sense in the bolt and nut to hold the original handle in place, and the cotter pin was a nuisance, so I turned the "belaying" pins to hold the handle in place. I made the one that goes through the 2 straps a bit thicker to accommodate the larger holes in bracket. (It bothered me to have the original handle flopping around if I disconnected the cotter pin and left the bolt attached. With the 2 pins, it's a cinch to completely remove the handle when I am using a dead center on the tailstock.

I bit of stain and 3 coats of rub on poly on the wood and done.”

Karl also sent these pictures of a Taig made button for his jeans.

Karl also sent these pictures of a Taig made button for his jeans.

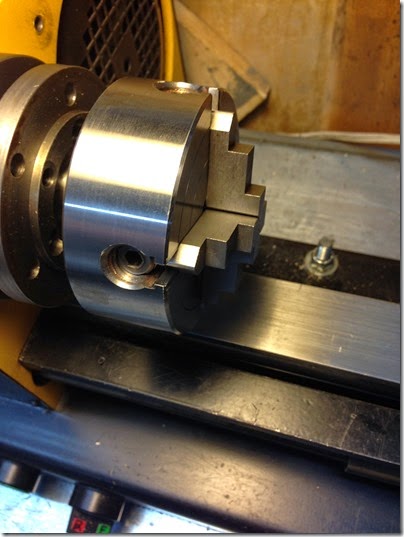

Jack Bonofey’s Taig Chuck On His Prazi Lathe

Jack Bonfoey mounted a Taig chuck on his Prazi lathe:

“Here is the story and a few pictures of the Taig chuck on my Prazi SD-300 lathe.

By the way, this is the link to the yahoo group where this started: http://groups.yahoo.com/neo/groups/prazi-machining/conversations/messages/161

I wanted a 4-jaw independent chuck for my older Prazi SD-300 lathe, but I don't believe you can buy one any longer. I heard some folks where having a "register" (recess) cut into the back of a Taig 1030 chuck and adding studs to mount it like the Prazi 3-jaw chuck. There is a person in United Kingdom who will do this, but with shipping and difference in exchange rate it would have been over $200 (half of what I paid for the used lathe).

So, I got the idea to buy an 2MT to 3/4"-16 arbor from Little Machine Shop and just screw on the Taig 1030 chuck. I happened into your website when searching for a Taig chuck, and I've been pleased with the support I've got from you. I also liked the quite affordable Taig accessories that screw-on to the 3/4"-16 spindle.

I put it all together today and it had a little over .003" run out on the face of both the chuck and the face plate. So, I took your good advice and did a very light facing cut on the arbor right where the chuck and face plate mount. In the attached arbor picture the cut would be right on the nut portion of the arbor facing the camera. Then it went down to less than .001" run out, which is more accurate than about anything I can do.”

Pat Miller's Taig Mounted On A Larger Wood Lathe

Eldon Johansen's Taig Mill Modifications

“A 1/4-20 bolt runs all the way through the spindle body. (the 10-32 threads and clearance hole on the dovetail clamp have been drilled out for 1/4th inch clearance)

I highly recommend making this modification!

I made a cradle from about 40 pounds of 1.25 inch wide angle iron 1/4th thick. (left over from a failed project) and it worked well, but i would do it again differently ( actually, i did, i'll upload some new photos soon.) (the new cradle i built is cement filled 2 inch square steel tubing.) another modification that is visible in the photos but hard to make out is i removed the bar behind the Z axis and mounted it 4 inches higher, then welded a brace on the back of the mill. (i'll get a few more photos soon) (however, i don't recommend anyone do this because welding the bar will warp it, i spent some time with a file and a grinder to smooth it out, even a few thousanths of warpage will cause the Z axis to bind) the reason why i did this is because the mill only has 5 inches of Y axis travel for the first two inches of Z axis travel. the Z axis leadscrew and ways get in the way, and the stock arrangement has the axis of the spindle sitting 3.75? inches away from the leadscrew.. i've run things into the leadscrew before...

Another modification i made was to flip the Y axis ways over, so they extend an inch further out toward the operator. 1.5 inch long steel tube sections hold the y axis stepper motor 1.5 inches further toward the operator.flipping the ways over will also compensate for wear by swapping left and right.

flipping them end over end will move one of the mounting holes, and you will have to drill and tap one hole in each one (might not be necessary for light milling)”

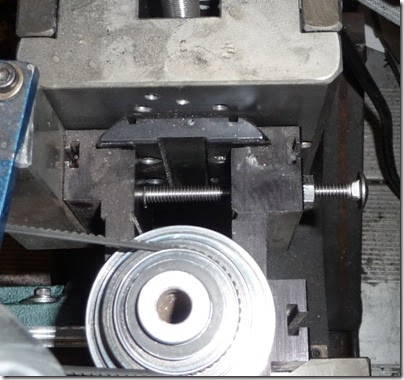

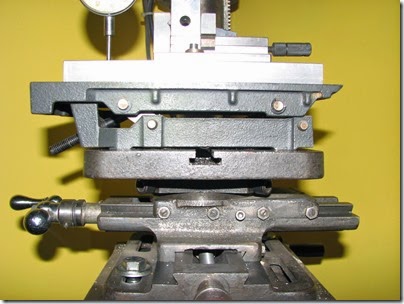

Lou Somer’s Home Brew Drill Press Milling Rig

“Here are a few pics of a home brew drill press milling rig I've tinkering with if you would care to post them. Previous to this I stacked feeler gauge blades to shim the quill down. It worked but it was an ordeal at times. This set up eliminates all the aggravation. It uses an infeed table from a 4" wood jointer. Depth of cut is controlled by an elevation screw. The advantage to this rig is that the quill stays in the home position where it is the most stable. Pictures show an action shot, table down, table up, and the elevation screw. This table raises about 1/2". Since it's on a pivot it also moves to the right about 5/8" at full elevation making it best to do grooves and shoulders on the x axis.”