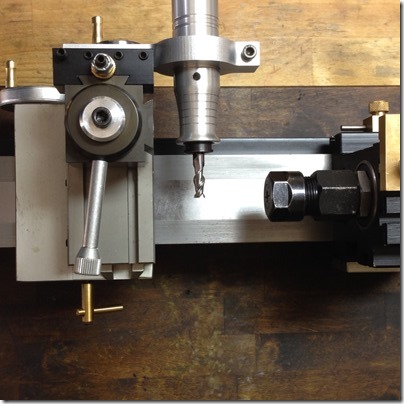

Took me all day but I managed to make this. This one fits in my QCTP. It allows me to be able to put the flex shaft further away from the piece in cases where I'm turning/milling a larger object. You made me do it! ;)

Wednesday, May 31, 2017

Jay Friedman’s Motor Mount

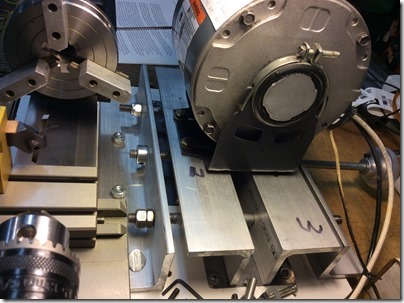

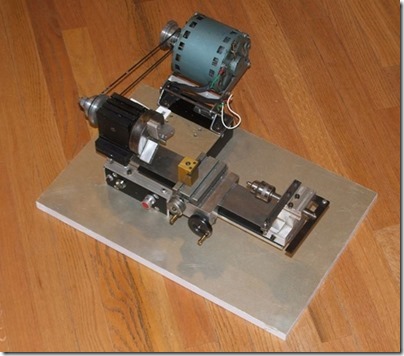

I recently made the motor mount you laid out in a drawing with the following description on your web site: "Motor mount A crude sketch of a useful motor mount I use on the Taig lathe". Two photos are attached.

I made it from aluminum angle pieces and 3/8" threaded and unthreaded rod as well as the necessary nuts and collars as per your drawing. I added a turning handle to the end of the threaded rod that I purchased. In addition to what was included in your drawing, I tacked a thin sheet of shimming material under the sliding components of the new motor mount to form what I call a "wear pad" to minimize wear on the Taig mounting board. It was not particularly difficult to make except it took some experimenting with different circumference Gates belts fore I had the right 450 mm. belt. Using a string around the pulleys didn't seem to work and they are only a few dollars on amazon.com.

I use a 1/3 hp Dayton 1075 rpm capacitor motor I bought on ebay for $40. It is physically smaller and lighter than the usual 1725 rpm motors, and I like that it turns the lathe a bit slower.

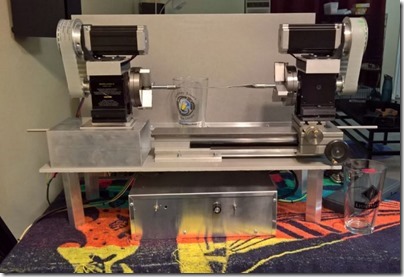

Jeffrey Shirley's Extremely Clean And Well Constructed Cased Lathe Mounting Board

I don't use my lathe too often, and wanted a way to keep it safe and clean during off periods. The lathe bed stores upside down above the motor, The sleeve with the carrying handles folds flat to take up less room when the lathe is in use. The table halves are held together at each end by hinges with removable pins.

Doug Jones’ Poor-man's Taper Attachment And Taig Tool Post Modifications

Poor-man's taper attachment (and spindle center).

I decided that I wanted a headstock spindle dead center in the style Dean Williams described here:

-- http://www.deansphotographica.com/machining/projects/headcenter/headcenter.html

I started with a chunk from an old 1/2 inch wheel bolt from a lawnmower. I already knew that this was a fairly hard steel bolt.

First, I turned the small tubular extension that goes beyond the taper, then drilled and tapped my chunk of steel 1/4-20 to fit the drawbar for my headstock depth stop. For drilling and tapping, I used the follower from my taper attachment as a handle on the tailstock. That's where it spends most of its time since I can squeeze it like a bicycle brake handle to put pressure on a drill.

Tapping the hard steel of the old bolt required quite a bit of force. As you can see in the photo, it kept slipping in the 3-jaw chuck, so I used a pair of vice-grip pliers to grab the bolt. 3 rubber bands (the kind they use to bundle broccoli) were just right to put pressure on the dead center that held the tail of the tap-wrench during tapping. Photo shows the tapping setup.

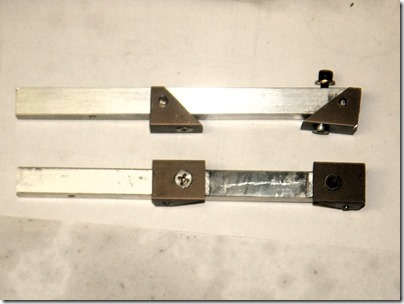

Then, it was time to turn the 15 degree taper. I pulled out the "poor man's taper attachment" that I made last year. This consists of two 1/2 inch square aluminum bars that clamp onto the Taig bed dovetails. The clamps are pieces of 3/4 inch architectural aluminum channel (with a 1/8 inch wall thickness) hinged to the bar. The near-side clamp-screw goes through the bar and works from the top. The far-side clamp-screw is permanently tight from the bottom, with a 1/8 inch shim holding it parallel to the bar. Photo shows the bars.

I clamped the bars to the bed and then scribed reference lines parallel to the bed on the top side of the bars for use in setting tapers.

To use these as a taper attachment, I clamp the steel rule from my square to the two bars, setting the bars, say, 8 inches apart (as far apart as I can for the taper angle desired). Then, using a dial caliper set to 8 times the tangent of the desired angle, and measuring relative to lines scribed on the top side of the bars.

To set up to turn a taper, you set the point of your turning tool at the point where the taper begins, then loosen the follower and slide it out until it bumps the ruler. Then, tighten everything down. Photo 2747 shows this point.

Then, back off the cross-slide, advance a few mils into the work, and make a facing cut until the stop runs into the ruler. Repeat this all the way up the taper, making a staircase of facing cuts, where the diameter of each cut is determined by the stop running into the ruler. Finally, return the cutting tool to its starting point at the far end of the taper and drive the carriage toward the headstock by hand, backing off on the cross-slide to allow the taper attachment to push the carriage back toward you. This finish cut removes the staircase and leaves a nice taper. Photo shows the result.

Finishing the headstock center isn't exciting, except that using this taper attachment to turn a 60 degree taper, I had to push the two bars so close together that the carriage only had under an inch of travel. This was tight, but enough to turn the final point. Leaving the taper in place in the headstock, I ran the tailstock dead center up to it and looked at them under my inspection microscope. Dead-on and no wobble when I turned the spindle by hand. That's not bad at all.

Taig toolpost modifications

I looked around at the various toolposts people are using on the Taig, and I saw that some people have gone in for elaborate and expensive quick change tooposts, while others note that the stock toolpost is almost as quick to change and dirt cheap. My main problem with the stock toolpost is fiddling with the nut on the bottom when trying to get it into the T-slot. Why is the nut on the bottom? Then I saw Irv Bakeland's modified T-slot nut and inspiration hit.

Why not use a 1/4 inch bolt with its head modified to fit the T-slot? That means drilling out the hole in the toolpost. I did this on the Taig lathe as follows:

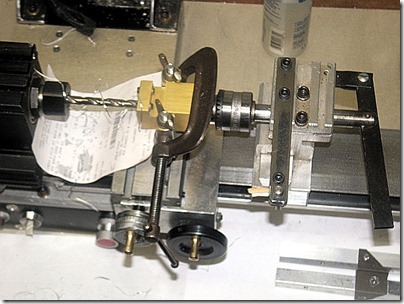

First, clamp the stock Taig toolpost between centers over the cross-slide and crank lock the tailstock to hold the toolpost perfectly centered. See photo.

Second, clamp the toolpost to the cross-slide. I used a pair of 1/2 inch square posts, drilled 1/4 inch down the center and mounted on the cross-slide with a pair of my modified T-slot bolts. Loosely tighten the bolts just enough that you can slide them snugly against the toolpost that's floating above the lathe bed, then loosely C-clamp the toolpost between the 1/2 inch posts. With everything loosely clamped, you know you're not disturbing the centering of the toolpost. Now, tighten everything a bit at a time making several rounds over all the screws until everything is solid. See photo 2754.

Now, you can back off the tailstock, back off the carriage, and mount a 1/4 inch drill in the headstock collet holder. Then, put something on the tailstock to use to push the carriage into the drill. I don't like using the hand crank for this, it sometimes takes too much torque on the crank to get enough pressure on the drill. Better to use the tailstock lever for drilling. Let it push the carriage forward. Here, I did something mildly evil, I used the jacobs chuck as a pusher, with the chuck opened all the way so it would clear the 1/4 inch drill when it came through. It would be better to use something like a die holder or just a block of scrap threaded to screw onto the tailstock center. See photo, taken midway through drilling.

Photo shows the final result. I could turn nice little collars to fit the top of the toolpost(s), but for now, I'm just stacking brass washers high enough that my wingnuts clear the set screws. I'll probably make high collars eventually, so I can replace the setscrews with cap screws. (What's that receipt on the lathe bed? I've found that it's easier to use paper to catch the swarf than it is to sweep up, so I frequently lay bits of paper around the cutting area. Aluminum swarf like I'm making in the photo isn't a big issue, but when I'm cutting hard metal like the headstock dead center, the swarf is frequently finely ground and very abrasive when I try sweeping if off of the aluminum parts.)

The bolts I'm currently using are grade 5 1/4-20 bolts. I mounted each bolt in the collet and turned the face (now the bottom) of the bolt head to remove the markings there, and then hand filed the bolts to width to fit the T-slots. This involved both filing 2 opposite flats on the side of the bolt head, and filing a "waist" on the top side of the head to fit the T-slot. Perhaps someday, I'll replace these bolts with grade 8 1/4-28 bolts, but there's no rush.

I particularly like the result for one simple reason: I can slip them into the T-slots without tinkering with the nut on the bottom to align it. You can do all the alignment from the top, and the wingnuts I'm using don't require any tools at all.

By the way, I forgot to put the URL for Bakeland's T-slot nut that inspired what I did. It's to an old post of yours, but why not keep things cross-referenced:

-- http://cartertools.blogspot.com/2011/11/irv-bakelands-extended-height-t-slot.html

Tuesday, May 23, 2017

John Wall’s Amazing A10C Warthog Cockpit

John Wall writes:

”I started metal working as hobby about 18 years ago. It was through your web site that I really became inspired to learn more. I began with a TAIG lathe and many of the tools and accessories I made were from ideas gathered from many of your links to Taig owners and their projects. Several years later I graduated to a manual Taig mill. It was fun but its use was limited mainly because of lack of projects for it. About 10 years ago I converted the mill to CNC. Unfortunately it still didn’t get much use and again I attribute that to a lack of projects for it to become involved with. However that all changed when I started building large scale model ships from scratch. The Taig CNC mill became an extremely useful and almost indispensable tool. As I got a lot more experience, I wanted to find a real challenge. So, three years ago I began building a fully functional replica cockpit of an A10C Warthog aircraft. The cockpit is integrated into a PC simulator by the name of DCS World, Digital Combat Simulator. As of this date, it is still under construction and the Taig CNC mill has seen daily use over that year period. It has hundreds upon hundreds of hours of mill time associated with it.

I have maintained a photo site of all of the components that I have built to date. Most everything in the cockpit has to be made from scratch because, if the parts were purchased, they would have cost a small fortune.

I bring this to your attention because almost everything involved in the construction of the cockpit was in some way related to the Taig CNC mill. Over 50 circuit boards were milled. 30 or more panels were milled and their faceplates engraved using the Taig mill. Most of the knobs were milled to make mold's. Displays bezels were cut. More than 20 gauges were fabricated using the Taig mill and over a 100 keyboard keys cut and engraved. It has been an almost overwhelming task. I have to attribute my success in creating all of these parts to the Taig CNC mill. Without it, this would have been an impossible task.

Have a look through my photo sites and see what I have been able to build with this fabulous tool. If you wish to add anything to your web site to show your readers what the mill is capable of, you are more than welcome.

http://s221.photobucket.com/user/MRAR15/library/?sort=3&page=1 over 350 pictures of cockpit

https://flic.kr/s/aHsk5pNVQz more cockpit photos

https://flic.kr/s/aHskokbQ48 more cockpit photos

https://flic.kr/s/aHsjFBvpK4 (Model Ship built with Taig CNC Mill)

https://flic.kr/s/aHsjFxQsgV (Model Ship built with Taig CNC Mill)”

Tuesday, August 23, 2016

Doug Jones’s Taig Lathe

“I'm making progress on the fan hub for my motor, and in the process, I found another use for the pins I made that fit the holes in the soft jaws. After boring the rough blank and making the necessary cuts on the face of the hub, I clamped it to a piece of 1/2 inch bar that serves as a mandrel to hold the hub. Turning off the roughly hacksawed circumfrence produced lots of impact loadings on the much smaller diameter mandrel, loads that would easily cause it to slip in the chuck, so I stuffed one of the pins back into the hole in the chuck jaw to serve as a dog. This worked quite well.

I took the photo just prior to the final clean-up cuts on the exterior of the hub. Most of the hacksawed perimeter of the hub has been converted to swarf -- and if you look at the tool, it's a 3/16" square shank boring bar, shimmed to fit the tool holder. It has cutting edges in the right places, so I used it. The carriage depth stop is really handy when you're cutting right up to the jaws as I am in this case.

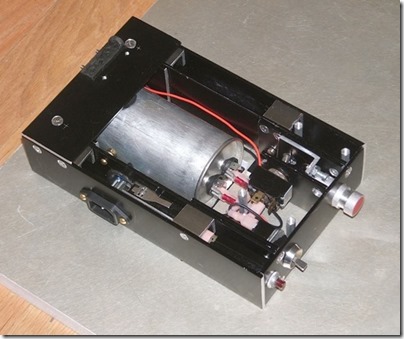

When I got my lathe off E-bay last year, I mounted it temporarily on a chunk of scrap wood. This spring, I started to build a nice base for the lathe. It's not quite operational yet (I need to do the fine adjustment on the belt alignment and then connect the motor wiring) but it's finished enough to show off in some photos (attached).

The baseboard is made of MDF (a leftover cabinet door cut down to size) with an aluminum plate (the lid of a surplus bit of electronics junk) epoxied to the MDF as a work surface. I used about 300 pounds of sand bags to clamp the assembly, and then I used a router to carve off the final 1/8 of an inch all around to square up the edges. Routing aluminum, you get a lot of chip welding unless you scrape beeswax onto the edge you're going to cut. That completely solves the problem. After cutting, I painted all the cut edges.

The on-off switch, circuit breaker and reverse switch are built into the pedestal, along with a microswitch that currently powers everything down if the top cover is opened, but will eventually interlock with a belt guard. The motor is a salvaged GE 1/4 horse capacitor-run motor, so it is easy to reverse, but it takes a fairly large capacitor. That fills a good chunk of the pedestal and sits in a well routed into the base.

The pedestal is made of scrap 1 inch wide by 2 inch deep extruded architectural aluminum channel, with some smaller chunks of 3/4 by 3/4 inch channel for bracing.

The motor mount is calculated to put 12.5 pounds of weight on the belt, based on a 10 pound motor (I weighed it first, then did the motor mount calculations). That's based on the Gates recommendations for the tension on their series 3M belts -- they suggest a minimum tension per strand of 5 pounds, and a maximum of 7.5 pounds. For two strands (a full loop of belt), that's a total tension of 10 to 15 pounds, so I aimed for the middle.

The motor mount allows the motor to flip inward to make a small package for storage, or to hang out of the way in back to run the lathe. Working out the details of that led me to buy a Gates 3M650 belt. This is actually shorter than the 5M800 belt that came with the lathe when I bought it from E-bay. I have no clue how its original owner mounted it. Perhaps it was a below-the-bench motor mount.

The on-off switch in the base is a pull-on, push-off switch. Inside the base, you can see that it's just a plain toggle switch, with a knob that pushes and pulls the toggle. The knob has hard stops in both directions, so you never put stress on the switch handle no matter how hard you bang the knob to turn off the lathe. There's a grip turned on the aluminum knob for pulling, and the front has a red PVC insert (convention says that pushing a red switch ought to turn things off). I knew that I wanted a red insert, but how to make it? The answer turned out to be polymer clay. I used Sculpy Primo, but I suspect that Fimo or regular Sculpy would work about as well. I turned a tapered hollow in the front of the knob, and then cut grooves into the taper so that when I pressed in the polymer clay, it would lock in place. Then I baked the entire knob to turn the clay into hard PVC. The finish on the front face of the PVC was achieved by pressing the soft clay in place against a sheet of saran wrap against a clean countertop, and then carefully peeling off the saran wrap and blotting up the thin layer of clay that remained on the aluminum edge of the front face.