Poor-man's taper attachment (and spindle center).

I decided that I wanted a headstock spindle dead center in the style Dean Williams described here:

-- http://www.deansphotographica.com/machining/projects/headcenter/headcenter.html

I started with a chunk from an old 1/2 inch wheel bolt from a lawnmower. I already knew that this was a fairly hard steel bolt.

First, I turned the small tubular extension that goes beyond the taper, then drilled and tapped my chunk of steel 1/4-20 to fit the drawbar for my headstock depth stop. For drilling and tapping, I used the follower from my taper attachment as a handle on the tailstock. That's where it spends most of its time since I can squeeze it like a bicycle brake handle to put pressure on a drill.

Tapping the hard steel of the old bolt required quite a bit of force. As you can see in the photo, it kept slipping in the 3-jaw chuck, so I used a pair of vice-grip pliers to grab the bolt. 3 rubber bands (the kind they use to bundle broccoli) were just right to put pressure on the dead center that held the tail of the tap-wrench during tapping. Photo shows the tapping setup.

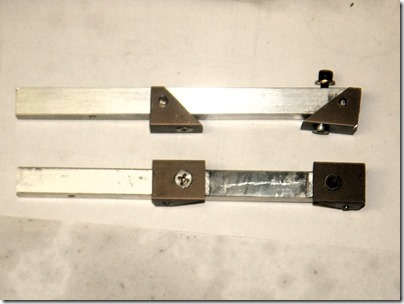

Then, it was time to turn the 15 degree taper. I pulled out the "poor man's taper attachment" that I made last year. This consists of two 1/2 inch square aluminum bars that clamp onto the Taig bed dovetails. The clamps are pieces of 3/4 inch architectural aluminum channel (with a 1/8 inch wall thickness) hinged to the bar. The near-side clamp-screw goes through the bar and works from the top. The far-side clamp-screw is permanently tight from the bottom, with a 1/8 inch shim holding it parallel to the bar. Photo shows the bars.

I clamped the bars to the bed and then scribed reference lines parallel to the bed on the top side of the bars for use in setting tapers.

To use these as a taper attachment, I clamp the steel rule from my square to the two bars, setting the bars, say, 8 inches apart (as far apart as I can for the taper angle desired). Then, using a dial caliper set to 8 times the tangent of the desired angle, and measuring relative to lines scribed on the top side of the bars.

To set up to turn a taper, you set the point of your turning tool at the point where the taper begins, then loosen the follower and slide it out until it bumps the ruler. Then, tighten everything down. Photo 2747 shows this point.

Then, back off the cross-slide, advance a few mils into the work, and make a facing cut until the stop runs into the ruler. Repeat this all the way up the taper, making a staircase of facing cuts, where the diameter of each cut is determined by the stop running into the ruler. Finally, return the cutting tool to its starting point at the far end of the taper and drive the carriage toward the headstock by hand, backing off on the cross-slide to allow the taper attachment to push the carriage back toward you. This finish cut removes the staircase and leaves a nice taper. Photo shows the result.

Finishing the headstock center isn't exciting, except that using this taper attachment to turn a 60 degree taper, I had to push the two bars so close together that the carriage only had under an inch of travel. This was tight, but enough to turn the final point. Leaving the taper in place in the headstock, I ran the tailstock dead center up to it and looked at them under my inspection microscope. Dead-on and no wobble when I turned the spindle by hand. That's not bad at all.

Taig toolpost modifications

I looked around at the various toolposts people are using on the Taig, and I saw that some people have gone in for elaborate and expensive quick change tooposts, while others note that the stock toolpost is almost as quick to change and dirt cheap. My main problem with the stock toolpost is fiddling with the nut on the bottom when trying to get it into the T-slot. Why is the nut on the bottom? Then I saw Irv Bakeland's modified T-slot nut and inspiration hit.

Why not use a 1/4 inch bolt with its head modified to fit the T-slot? That means drilling out the hole in the toolpost. I did this on the Taig lathe as follows:

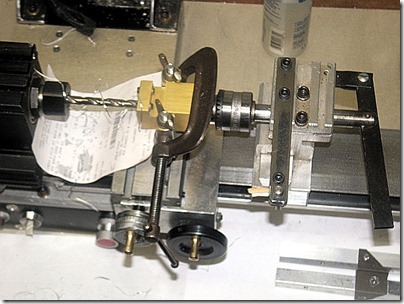

First, clamp the stock Taig toolpost between centers over the cross-slide and crank lock the tailstock to hold the toolpost perfectly centered. See photo.

Second, clamp the toolpost to the cross-slide. I used a pair of 1/2 inch square posts, drilled 1/4 inch down the center and mounted on the cross-slide with a pair of my modified T-slot bolts. Loosely tighten the bolts just enough that you can slide them snugly against the toolpost that's floating above the lathe bed, then loosely C-clamp the toolpost between the 1/2 inch posts. With everything loosely clamped, you know you're not disturbing the centering of the toolpost. Now, tighten everything a bit at a time making several rounds over all the screws until everything is solid. See photo 2754.

Now, you can back off the tailstock, back off the carriage, and mount a 1/4 inch drill in the headstock collet holder. Then, put something on the tailstock to use to push the carriage into the drill. I don't like using the hand crank for this, it sometimes takes too much torque on the crank to get enough pressure on the drill. Better to use the tailstock lever for drilling. Let it push the carriage forward. Here, I did something mildly evil, I used the jacobs chuck as a pusher, with the chuck opened all the way so it would clear the 1/4 inch drill when it came through. It would be better to use something like a die holder or just a block of scrap threaded to screw onto the tailstock center. See photo, taken midway through drilling.

Photo shows the final result. I could turn nice little collars to fit the top of the toolpost(s), but for now, I'm just stacking brass washers high enough that my wingnuts clear the set screws. I'll probably make high collars eventually, so I can replace the setscrews with cap screws. (What's that receipt on the lathe bed? I've found that it's easier to use paper to catch the swarf than it is to sweep up, so I frequently lay bits of paper around the cutting area. Aluminum swarf like I'm making in the photo isn't a big issue, but when I'm cutting hard metal like the headstock dead center, the swarf is frequently finely ground and very abrasive when I try sweeping if off of the aluminum parts.)

The bolts I'm currently using are grade 5 1/4-20 bolts. I mounted each bolt in the collet and turned the face (now the bottom) of the bolt head to remove the markings there, and then hand filed the bolts to width to fit the T-slots. This involved both filing 2 opposite flats on the side of the bolt head, and filing a "waist" on the top side of the head to fit the T-slot. Perhaps someday, I'll replace these bolts with grade 8 1/4-28 bolts, but there's no rush.

I particularly like the result for one simple reason: I can slip them into the T-slots without tinkering with the nut on the bottom to align it. You can do all the alignment from the top, and the wingnuts I'm using don't require any tools at all.

By the way, I forgot to put the URL for Bakeland's T-slot nut that inspired what I did. It's to an old post of yours, but why not keep things cross-referenced:

-- http://cartertools.blogspot.com/2011/11/irv-bakelands-extended-height-t-slot.html

No comments:

Post a Comment