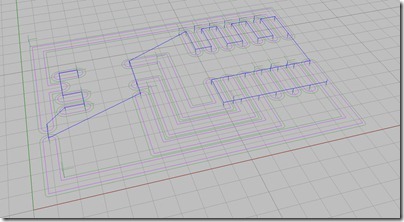

“Hand” drawn PCB in Rhino with toolpaths done in MadCam.

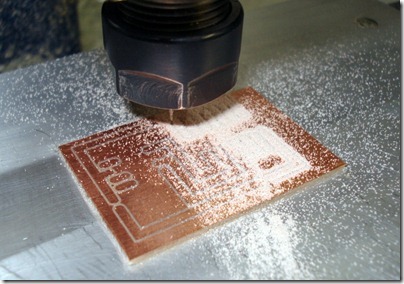

Milling with a .020” carbide end mill.

Another shot.

Very clean, no burrs.

Holes drilled with a #59 carbide circuit board drill.

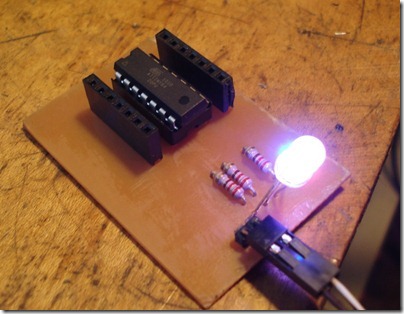

Soldered up and working. It’s an Attiny84 microprocessor driving an RGB LED with PWM so I can get a lovely mix of colors. The headers on either side of the chip are for reprogramming and additional utility. I'm using an Arduino to program the Attiny84.

That piece of material doesn't look like it is being held down. is it glued? How'd you get it up and what is the material? Plain copper?

ReplyDeleteIt's a one sided blank PCB. You can get them from any electronics supplier, radio shack, etc. It's about .002" thick copper bonded to a phenolic board. I used double stick carpet tape to hold it down to a tooling plate.

ReplyDeleteTurning tape would also be an alternative if you needed a little more "stick"

ReplyDeleteNIck,

ReplyDeleteCongtrats!

Fwiw: Use some super glue half a drop in each corner and center....

do your milling.... then pour some acetone on it and it'll come right up.

thats ow I do it it works perfectly. also allows you to deal with those boards that are not perfectly flat too. I should post up some pics of my PCB board jig.

Good tip, I'm going to build a jig as well soon so it would be great to see yours.

ReplyDelete