I have been quiet just lately, but this week I decided to address a major moan of mine - the short comings in the design of the drilling tailstock, I have previously mentioned the reduction of ram side loads on the air gap due to linkage geometry, (easily accomplished by increasing the hole spacing on the lever by 1/16"). However the problem of side loads on the 1/8" clamping air gap remained so I rotated the arm assy., through 90degs., to the vertical position, I recycled a piece of 1"x1/2" ally from an old project, milled a slot and drilled a hole to accept the Taig links from the top location. This assy., is bolted onto the back of the tailstock under the overhang, as per the pictures. Now the loads are on the top and bottom of the clamping surfaces. I can still hang my hat on the lever and there is a smaller bench footprint. The only disadvantage I have found so far is that in this configuration the assy., can not be rotated on the bed but if a bracket and linkage assy., is mounted on top using the T slots then this is possible but then the lever action is reversed! Oh well, you can't have it always - yet!

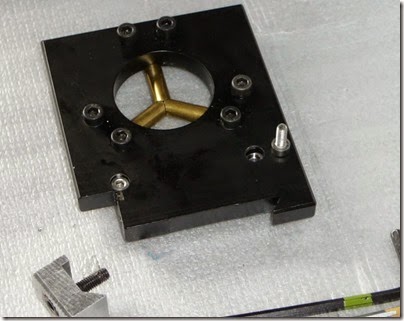

I elected to fabricate a T bracket with two swinging links and a new lever assy..

Here is the arrangement with the overhang at the rear

Here reversed.

Two more pictures to add to the last batch.

I decided to modify the handle by having two sets of holes, to cater for either set up. A new pin and the holes reamed out, everything is really sweet, it feels much better than the standard side mounted system.

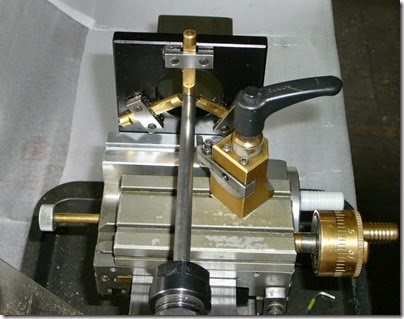

Modifications to the threading setup. The modifications involve simplifying the construction and beefing it up a little.

The machined rod guides that clamp to the headstock have been replaced by two 1 1/2" washers with a flat filled on each to clear the spindle and a clamping bolt. The rods have been changed to 5/16" diam.

So the main components are still three threaded rods, three bits of sq., ally from the scrap box, the through the spindle attachment for the thread samples and the delrin cartridge to accept the same.

The washer seats the rods on the corner of the bed /headstock junction.

The rods centralise the washer over the void.

Here it is installed- I Photoshopped the lathe out.

I have just spent a disgusting amount of money on a new mill ( Seig X3???) and thought it advisable to check on the web for tips. Well that got me worried so I set mine up the best I could an noticed I had 80 division of slack (2mm) in my fine feed knob!!! Well there was end play and axial play, I shimmed most of the axial play out but the the flexi coupling rattled as it was made in the wrong shack, check the alignment in the pics.,it must have been drilled with a hammer!

To make matters worse the worm gear shaft presessed instead of rotating, only by leaving the bearing block loose could I get free rotation of the input dial! I could see that the only solution would be a new shaft and universal joints. So- I had a cup of tea then attacked a piece of delrin rod with the Taig, the result is shown in the pictures.

A pair of slots at 90 degs., at each end and 45 degs., between them, as long as the shaft drillings are short of the slots, it works a treat. There is sure to be another sucker out there with the same problem, I hope this helps.

If I am so clever how come it took me 24 hours to realise that the flexi milling shaft mod., I have sent you will also get round one of my pet hates of the power drive, the spring connection. I have just measured an axial movement of 0.125" on my lathe.

Here is a picture of my original solution to this problem - a bit of work, now residing in my scrap box.

So all I did this time was turn a piece of delrin down to 16mm od and a length of 2.2", a 1/4" diam., 1/2" hole at the input end. The other end finished up at 6.9mm diam., by 5/8" deep to accept the spring end of the power drive. Drill and tap for lock screws. Two pairs of opposed slots were found to give enough flexibility and with no measured end float apart from 0.001" on the gearbox output shaft.

A while ago I saw a video on YouTube of manufacturing "smooth twist" barrels and as usual I fortified myself with a cup of tea and pondered. I came up with a simple jig that could swap between different twist rates and also progressive twist. The initial results showed promise as can be seen from the over cooked sample in the picture.

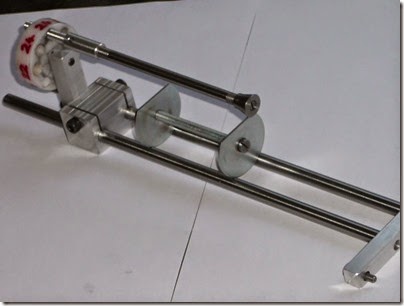

Working with thin tubing showed I needed a travelling rest and a method of mounting the same, so a long overdue attachment was born, using my new mill. I built up a bridge T slot and mounted it on the carriage, with clearance for a hex key to make adjustments. I used two 4mm screws with the heads turned down to 5mm to slip in the T slot for fixing.

design for a rest came to mind but I did a quick mod., job to the Taig fixed rest and bolted it to the rear face of my T slot (I shimmed it 0.010" over the bed for location).

Picture is not work in progress but just a set up