Thanks Irv!

A Blog containing the latest news, projects and pictures about the Taig Lathe and Taig Milling Machines. A complement to my main Taig Lathe pages at cartertools.com

A customer was wondering how the #1200 Top Slide is mounted to the Taig Lathe cross slide.

If you flip the 1200 over you see it has a recessed circular dovetail. The nut fits into the circular slot and the screw draws the two halves together, pulling the top slide down and locking it into position.

How the nut fits in the circular dovetail.

I find it’s easiest to loosen the nut and slide it into the cross slide t-slot first.

Then place the top slide over it. It takes a little practice but after a while becomes easy.

The hex wrench tightens the nut from the back side (you can do it from the front but only on the right t-slot as the cross slide screw bearing block is in the way of the left one. I snug the nut up but don’t fully tighten…

Then I hold a protractor against the side of the slide and the front of the cross slide, get it set to the desired angle and fully tighten the nut. You don’t want to use a lot of torque. If you find that the 1200 top slide shifts or moves then you can place a thin piece of paper between the cross slide and the top slide. Also you can’t take heavy cuts. I generally take about .01” cut max.

Taking a cut in free machining steel. Notice how the tool bit mounts directly to the top of the slide.

After a few passes.

Frankie Flood shows his y-axis extension on his blog.

Ray Johns’ forum post showing his adapter for a pressure gauge on his espresso machine.

I have also just noticed that the bracket could be left in place when the tailstock is repositioned normally, and that it might be beneficial if the ram works against the brass edge then some load is taken off the air gap and is transferred to the clamping bolt assy.? (I did drill the hole first then file the edge until I had a running fit with no rocking evident.)

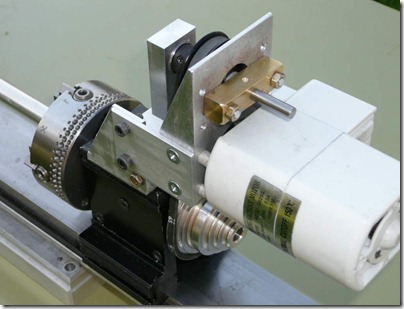

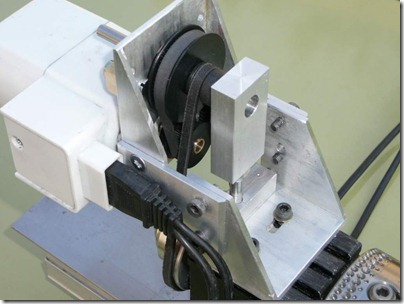

Well you suggested fitting a worm /gear assy., to my headstock spindle to do some indexing work, so that is where I started from.

My attempts to come up with a solution that involved a quick flip down, engage gear and brake assy., gizmo using brackets and plates eluded me for hours but as usually happens I got inspiration from elsewhere in the form of a large hex key on my bench, so I came at the problem from a different direction, 90 degs in fact! What started out with a hex key now has more resemblance to a box spanner/tommy bar. I will try and put the pics in some sort of order with a few words of explanation of how I got 'tooled up' starting with a pic of my hex key and first experiments with mounting clamps and "T" bar arrangements.

A picture of all the removable components clockwise from top left - eccentric 1/4" location collar, 1/4" spacer, 1/2" eccentric brake mounting, brake/pinch bolt, 3/8" spacer, mounting arm with worm shaft bearing assy., the worm shaft and worm, seating collar for division plate, division plate/carrier/clamping bolt assy., thrust washer, shaft location collar, indexing arm assy., and securing screw/washer for the arm. What NO sector arms!!!!!A few notes on some of the above components, the spacers I managed to make out of an old syringe with an id of .75" they set things up axially to align the brake and worm when installing the system with my pulley mounted worm gear. The locating collar and the brake mount could be made from 1" diam bar and bored out eccentrically to match the main support arm, but I was lucky having some 1.25" x.25" ally tube that could be offset 1/16 in the chuck turned eccentrically to leave a 1/4" flange on the outside for the brake seating. The collar needs a small drilling for a tommy bar in order to rotate it and set the brake arm to spindle centers distance. The locating collar only needs drilling and tapping for a grub screw. The brake assy, is cut out from 1/4" ally sheet with one hole to clear the 1" diam., adjusting eccentric and at 1.666" ctrs., the other hole is 1.666" diam., (spooky!) to clear the plain portion of the Taig pulley. A saw cut joins the two holes and the edges were thinned down to 1/8" to give it a little spring. A small grub screw is fitted in the top, this is only nipped up once the eccentric is correctly aligned and the spindle/pulley runs free in the brake. The whole brake assy., should be free to swing on the arm. The pinch bolt is a 4mm hex head bolt, within an ally sleeve, the sleeve end is recessed at 7.5mm diam., and the bolt head was pressed into this using a vice.

The main support arm is .75" diam., and should have been 3.5" long (OOPS), the extra .25" I misplaced from the end was an alternative location for the brake assy., to be used when a gear/brake drum was mounted directly on the spindle. The scrap box supplied the tube but I had to fit a plug in the end but this plug would not be needed if the bar is solid. The arm is cross drilled and reamed out to .5 to accept the bearing tube.The worm shaft tube is .5" CDS with 6mm brass bushes glued in the ends, a .25" reamer is fed in after fitting. The bearing tube is located by a screw down the center of the support arm, this screw is not locked down and in tension, but is tightened by torque only (the head is loose). A tapping hole was drilled through both components (only one wall was needed), then a No 2 tap fed in slowly checking the fit of the bolt occasionally until the bolt end can just be seen protruding through the tube wall, when the thread was tight at the tube/arm interface I called it located. Several holes could be drilled and tapped to cater for different worm/gear combination's, and with an asymmetric arm location too a quick 180 gives a degree of adjustment.

The support collar for the division plate should really have been made from brass but the scrap box was lacking. The division plate carrier is ally, bored out to 1/2" to fit the bearing tube, the flange is .75" (Taig spindle fit). The div., plates are fixed to the carrier with 3 c/s screws @120 degs and .75" diam. The extended locking arm is brass and the knob on the end needs to be positioned so that it clears the div., disc radially but its edge is at least level with the the disc surface as it also functions as a datum/pointer. The sector arm is brass, slotted, standard issue but I've hung a clear pointer at one end for reading the protractor and a detent pin at the other.

The detent pin assy., was inspired by one of your emails Nick. The ratcheting pen top mechanism moldings and the spring were kept and a pin was turned from brass to replace the ink cartridge. The ally housing slowed me down as I had to set up my pull through threading system and cut an internal pen thread. Once I realized a spring needs room to function I was home and dry. The ribbed ally (brass later) sleeve permits frantic action without friction burns. The whole thing works a treat.

•The two pics, end on and side on saved me the trouble of drawing a quick sketch to show the layout.

•and a third...another I found that makes me think I should be off Tahiti "Two points to stbd., Mr. Christian"!

The mounting clamp on the headstock is 1"x1"x2" ally with a split .75" diam., hole. No registration plate was req'd, just holes at the corners fitted with screws and large washers. I used a ratcheting lever on the clamping slot, initially I had thoughts of slackening this off and jumping teeth while counting in 12s! but that is slower than winding the handle. As can be seen I used delrin gears from HPC, and the fact that I had some ready made components to mount the gear on the end of the pulley lead me to prepare the clamping face with some cut grooves.

The headstock was reversed and one of my older alclad div., plates was mounted on the spindle and my hex pin pressed into action, a bit mounted in the tool post on the cross slide and set to 7 thou did a splendid job, better than knurling I have examples of. While I had that system set up I reversed the head stock and mounted the dividing head assy., and clamped a previously prepared brass disc blank on the spindle for marking a protractor plate as per Tony Jeffree's article. I set the cut depth to 3 thou, many hours later and a quick polishing the markings were still crisp.

Preparing div., disc blanks. Brass sheet bored out to fit Taig spindle, soon to be mounted and turned to diam..

Installing the dividing head assy., on the head stock. Slide the arm into the mounting clamp, the brake will hang down and slip over the pulley assuming the eccentric has been adjusted correctly, when the location collar abuts the mounting tighten the clamp and check the spindle is free, then release and rotate the arm until the worm engages the gear and tighten the clamp on the arm again.

Mounted

The rotating division plate is my way of not making sector arms. To use it, release the div., plate clamp (datum) and detent pin, advance the disc assy., past the sector arm in DOR by the req'd number of degs/sectors, clamp it. Now wind forward to 'zero' and then the full number of turns as req'd.

Throughout the development work on this dividing head I was constantly referring to Tony Jeffree's two designs and one of the ways I can see I have to go is to use my spare headstock with the legs removed to enable me to mount the device elsewhere on my lathe. Another idea I must follow up is T.J's 120 hole div., plate working to 1/10 deg., but I calculated a disc of 4 1/2" diam., to give 120 holes surrounded by metal, not 3". However I like the idea so much I have found a solution. One set of 60 holes (evens) which could be at 2 1/4" diam., and then another set of 60 holes (odds) offset 3 degs., at a slightly larger diam.. I had better get drilling. It is just his 'egg sucking' I have to try now.

It seems that the majority of people going DC fit a large diam., pulley to drop the spindle speed down so I followed suit. Having some 2 1/2" bar and 5mm aircraft grade alclad sheet I set about fabricating some larger diam.,pulleys. I copied the standard Taig pulley small end to drive my gear box then added a 3/8" disc of 2 1/2 inch bar and machined a belt groove, the parts were joined using 3 c/s screws about 120 degs apart. Wanting to regain a facility I had on an old pulley system I fitted a 3 1/2" disc of 5mm alclad, this would give me a 1/4" and clamping ring clear of the head stock and a really large pulley diameter, the 5mm thickness being enough material for a belt groove. This plate was also attached to the pulley assy., using 3 c/s screws about 120 degs apart, this method of construction ensures that the parts only assemble in one configuration. Not wanting to waste an opportunity I decided to drill some index holes in the plate too, but did not know where. I made quick Bentley type index pin that clamps on outside of the 'T' slot, then out of curiosity I slipped drills into the 'T' slot to see if one would fit, not impressed I slipped in a length of 7/32 hex rod, a perfect sliding fit! So I made my hex index pin 2" long with a 60 deg., point on each end, I tapped a blind hole and screwed home a bolt and ground the head off, a bit of brass hex for the clamping nut and a sticky ally washer completed the job. Both types of pins could be used to mark the hole positions on the disc. The pulley disc assy., was removed from the spindle and fitted in the 4J chuck and the holes drilled. It was convenient having already added the indexing capability to my 4J. It has been noted that the 'T' slot dimensions in the h/stock are all the same, be it the old split type or the new one piece extrusion, but the PCD derived from using the index pins is different between the two h/stocks, here the new h/stock has the advantage in that my hex pin design fits the top or the back 'T' slot, only one pin needed to cover both sets of holes. I took several pics of the above procedures but it was when I was reviewing the shot from the back with my 3J chuck fitted that I got diverted! (Again) See the spacer washer I have to use?

Did you see where that washer was going to take me? Well I just imagined it 82mm diam., with holes in. I thought I would fabricate some index discs, that can be slipped onto the spindle when required to do those little jobs and clamped with 3J, 4J, Taig drill arbour, collet set or face plate. I was lucky enough to have some 16g alclad under the bench so I set to. First I cut out some 85mm oct., shapes and centred them in the 4J chuck, the middle was turned out to .75" diam., and the fit checked by reversing the chuck on the spindle. When the size was right the plate was removed and clamped back on the spindle using a Taig arbour and the O.D. turned down to 82mm. The back face was coated with a marker pen so that the two PCD scribed by the index pins showed up clearly and the disc reversed. Once the decision was made as to which series of holes were to be drilled and the method (I am spoilt for choice here as I already have a selection of gears, index plates and and my modified 4J chuck). The method shown in the pics is the fastest for doing the 72 hole series . I turned a stepped arbour in the 4J to take the 72 gear hub and the .75" disc and clamped them with a dished washer. The drill system was set up at the far end of the x slide, then lined up with the scribed marks and the slide locked. A hex key was clamped to a tool post at the near side of the x slide and set up to engage the gear teeth just before the drill touched. The drill size at these diams needs to be 3/32". 2 seconds/hole was a respectable rate! I transferred the other holes from my 4J chuck at 10 secs/ hole. A few points to think about, either lub the disc to save the ally when clamping or maybe use some steel sheet. The index pin profiles can of course be modified, in the case of pairing a disc with a 4J chuck then two shallow grooves at 2.76" and 2.2" diam on the back face will clear the points. And just to finish this train of thought, a full set of index holes could be drilled in the back of a face plate (next job). Another thought if a face plate has a 60 series of holes drilled on the back and a series of 72 around the the outside diam., there is a difference of 1 deg., in their angles? Hmmm. If I'm not careful I could get side tracked again.

I could not resist having a go at index drilling my face plate, I did what I had threatened to and having all my bits of kit from my index plate mod to hand, I marked the index pin hole location and set to and drilled the back of the face plate with 60 holes, then swapped things about and mounted the plate on the x slide and drilled 72 holes around the outside as per my 4J chuck mod..Now for those that are not aware of where all this is leading, the 60 hole ring has 6 degs between holes and the 72 ring has 5 degs between holes and the difference between them is - 1 DEGREE ! I knew this could be right handy but not how to make use of it. If all else fails I have a cup of tea and sure enough the solution (groan) appears. I just made a slot in the lever mounting used with my chuck mod., so that the lever assy., has vertical and lateral adjustment, only a few degrees needed, it will be in the pics. And now the procedure to tweak my face plate by any number of degrees. eg. REQ'D - Two degs C/W. Slacken 60 hole index pin rotate plate two divs (12 degs) c/w. lock with 60 hole pin. Align 72 hole index pin assy., clamp lever mounting and check index pin seated, withdraw 60 hole pin. Now rotate plate using the 72 hole ring, 2 divs (10 degs) a/c/w, seat index pin. End result 2 degs C/W movement. Well it was either solve that little problem or cut the grass!