Friday, March 25, 2011

PC Case Made With A Taig Mill

Tuesday, January 18, 2011

Steve Fornelius' Indicator Attachment

“Here's what I made so that I could mount my dial indicator on the headstock arbor. Using this I'm able to get the variance of the milling attachment to less than .001 easily.

The unit is simple to make: Use a blank arbor, drill halfway through with cut down 1/2 inch drill (available at any hardware store. I drilled and tapped a 10-32 hole to take a SHCS. Since you're not turning on the lathe with this in place it isn't important how long the screw is.

For the holder itself, II used a piece of 1/2" 12L14 stock about 3 inches long. I used a 3/8" mill and the milling vice to cut down both sides so the finished size is about 1/4" thick. The reason for this is to allow the dial indicator plunger and dial to clear the holder.I drilled a 1/4" hole in the end.

To use this, mount the dial indicator with 1/4-20 bolt and nut, then slide the holder into the adapter.and tighten down the set screw. Screw the adapter onto the headstock arbor. Put the work piece into the milling vice and move the cross slide down so that the indicator goes around at least once. Crank the cross slide until one side of the work piece is indicating and gently tighten the rear milling adapter screw. Crank to the other side of the work piece and note the difference in readings.

Then I simple twist the milling attachment so that the indicator reads 1/2 the difference. I keep moving the cross slide back and forth, adjusting out the variance until there is no movement of the indicator needle. Then I tighten down both milling attachment screws evenly and recheck the variance. The first couple of times you will probably need to loosen the screws and adjust again, but it works better than any other way I've tried. I can get a repeatable 0.0005 cut on the milled pieces when cutting grooves.”

Sunday, January 16, 2011

Peter Zicha's Taig Mill and Projects

“This is my Taig CNC mill as of today.”

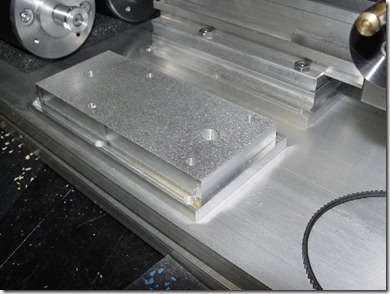

”I am starting to do the manual electric drive & CNC drive retro fit on both units machining parts . I made some 3/4 inch base risers for both units . one mounted and the other waiting for its partner in the mail . “

Saturday, January 15, 2011

Guy Zattau's Taig CNC Mill Limit Switches

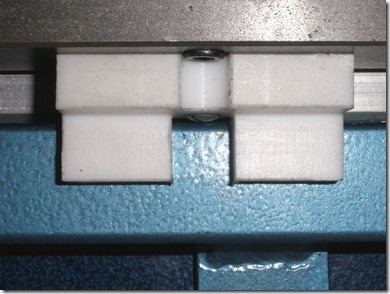

“Here's some pics of the setup and the limit switch arrangement with no holes drilled in the mill. The white things are the trippers and the run close to the brackets that hold the micro switches.”

Here are the pics of the mill limit switch brackets before being installed. #'s 1, 2, 3 are the X axis that mounts on using the holes for the rubber way protector. It mounts using the two end holes with access holes thru the top for an allen wrench. The rubber is sandwiched in between. The slot is 3/8" by 1/2" and the relief for the post is 3/8". Material is 1 3/4" x 1 3/4" x 6 1/2". I used .080" but it's a little too thick and makes it hard to get the trip levers to actuate the micro switches.

“Z, made from 1" x 2" x 7 1/2" x .058". It is mounted using the holes tapped in the vertical axis post that mounts the power switch. Compression posts made of tubing sleeve the holes. Holes on the part next to the post are clearanced for the screw and the ones on the outside are just big enough for the tubes to pass and finish up flush.”

“the Y axis, made of 1" x 1" x 8" x .058" with two brackets. The brackets are 2" tall with a 1 5/8" foot, 1" x 1 1/2"

wide. The micro switches are approximately 1" x 3/4" x 1/2" and are mounted with 4-40 countersunk screw so the moving parts clear. The trip devices are made of a Teflon like material machined to ride on the moving component just off the surface of the brackets and tripping the actuator lever of the micro switch. It may be necessary to add a piece of shim stock to the lever to make them work, I used .030, glued to the lever with epoxy. “

Here are the pics of the microswitch trip pieces for the mill. The Z is a simple angle piece with a small ramp cut at the top so it can allow the Z axis to go to the limit. X was made as one piece, then cut in half. Drilled the holes first then milled away the sides to leave a ridge. The ridge centers the part and prevents the screws from marring the groove in the table. Cut the 4-40 allen screws to length so they don't bottom against the back of the nut retainer slot in the table. The Y is a piece of work and difficult to get off as it is necessary to remove the microswitch bracket first. The drawing that is enclosed with the copy's I sent you is probably more understandable that what I can write. It's a goofy design but the best I could come up with at the time. All the material I sent you is just meant to be an idea and not an exact blueprint. Everyone should make their own measurements. The main theme was to not drill any holes in the machine, just use the existing ones.

Wednesday, January 12, 2011

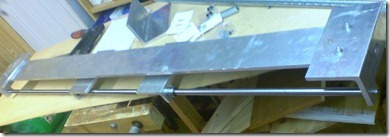

Håvard Buhaug's Extended X Axis Taig Mill

“I made an extended x axis. The axis is 1500mm long, and I made it for cutting rifle stocks blanks and other long wooden items. Attached some pictures from the setup and product coming out. The parts needed machining in order to make the axis were obviously made with the Taig.”

Friday, September 24, 2010

A Few Links

Here are a few Taig and Machining related links:

- Adam Collins started a blog about his adventures with a Taig Mill.

- Andy Rawson has a blog about robotics and his Taig Mill.

- Draftsight is a free CAD program from Dassault.

- Intracad Grasp 3D Laser Scanning Alpha (free for now?).

Sunday, September 12, 2010

A Plumbing Adapter

The faucet for our water filter broke and the new one had different plumbing than the old one. Rather than redo all the connections I made an adapter to go from the faucet (7/16”-24 UNF for a 1/4” compression fitting) to the tubing (3/8” compression fitting)

A piece of “medical grade” Pomalux Acetal Copolymer.

Center drilling

Drilling for the tap.

Tapping (under hand power…)

Drilling the rest of the way through 1/4”

Flipped in the chuck and turned down to 3/8” diameter for the compression fitting.

Milling a hex so I can get a wrench on it.

The finished adapter.

In place under the sink.

The new faucet on the sink. The picture makes me think I need to tear apart the whole kitchen counter.

Anyway, no need to drive to the hardware store, although I was lucky (or a good hoarder) to have the 7/16”-24 tpi tap on hand. It isn’t common.

Monday, August 16, 2010

Athena’s Inlay And Some Links

Athena sent in two pics of her first inlay tests using the Taig CNC mill.

A cross in silver and abalone.

"A shot of a little test I ran yesterday. I have tons of designs for fretmarker inlays. One is little silhouettes of various pistols and rifles. I did a test run of an Uzi to see what it would look like in real life. It's less than a half inch tall. My builder friend is going to make an M1 Carbine theme guitar I'm designing an inlay for right now, so guns are kind of a theme now."

And some links:

Caligari’s Truespace 3D Model software is now free

Dean put up details of his Taig mill Countershaft

Youtube video about a hidden door company that happens to use a Taig mill. (0:42 to 0:46)

Wednesday, June 30, 2010

Some Quick Clamps

I needed some clamps for holding word down on a sub plate that were less time consuming to adjust for workpiece thickness. This type of clamp is available commercially (Rite-Hite, etc) but at their simplest they can be made from tubing.

Sawing some scrap thick wall aluminum tube that was handy.

Sawn into thirds

Slotting on the Taig mill.

I radiused the ends and deburred on my belt grinder.

In an ideal world I’d make some washers that had a concave radius to match the pipe sections. But no need for now.