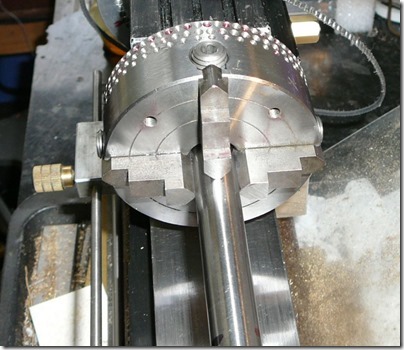

“I'm making progress on the fan hub for my motor, and in the process, I found another use for the pins I made that fit the holes in the soft jaws. After boring the rough blank and making the necessary cuts on the face of the hub, I clamped it to a piece of 1/2 inch bar that serves as a mandrel to hold the hub. Turning off the roughly hacksawed circumfrence produced lots of impact loadings on the much smaller diameter mandrel, loads that would easily cause it to slip in the chuck, so I stuffed one of the pins back into the hole in the chuck jaw to serve as a dog. This worked quite well.

I took the photo just prior to the final clean-up cuts on the exterior of the hub. Most of the hacksawed perimeter of the hub has been converted to swarf -- and if you look at the tool, it's a 3/16" square shank boring bar, shimmed to fit the tool holder. It has cutting edges in the right places, so I used it. The carriage depth stop is really handy when you're cutting right up to the jaws as I am in this case.

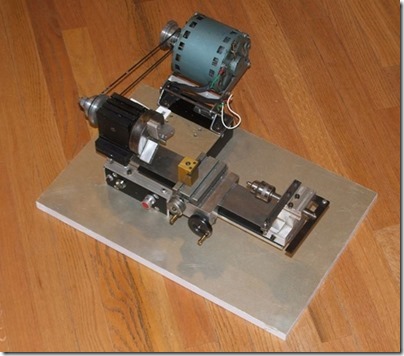

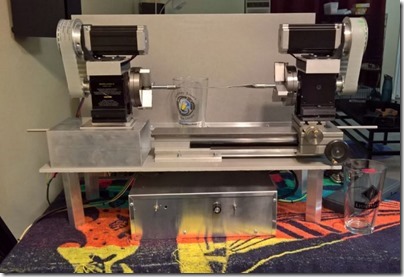

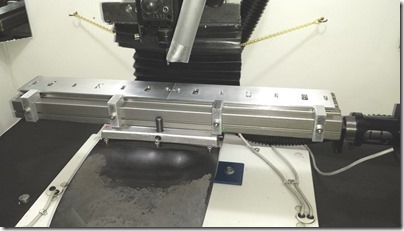

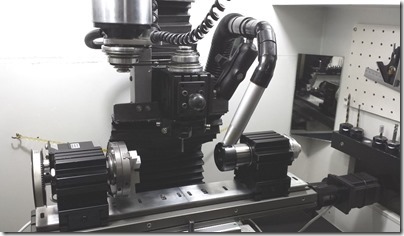

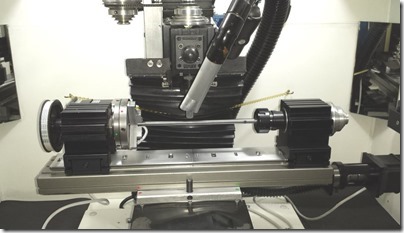

When I got my lathe off E-bay last year, I mounted it temporarily on a chunk of scrap wood. This spring, I started to build a nice base for the lathe. It's not quite operational yet (I need to do the fine adjustment on the belt alignment and then connect the motor wiring) but it's finished enough to show off in some photos (attached).

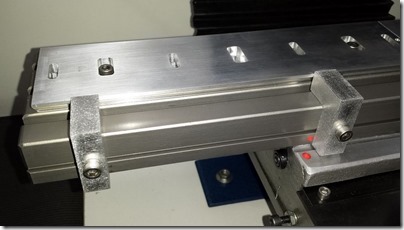

The baseboard is made of MDF (a leftover cabinet door cut down to size) with an aluminum plate (the lid of a surplus bit of electronics junk) epoxied to the MDF as a work surface. I used about 300 pounds of sand bags to clamp the assembly, and then I used a router to carve off the final 1/8 of an inch all around to square up the edges. Routing aluminum, you get a lot of chip welding unless you scrape beeswax onto the edge you're going to cut. That completely solves the problem. After cutting, I painted all the cut edges.

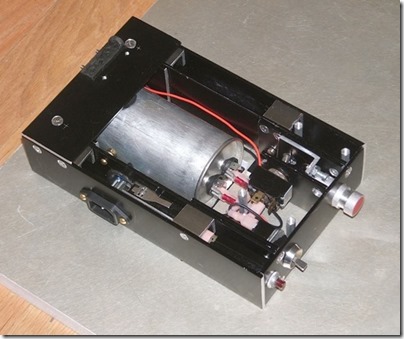

The on-off switch, circuit breaker and reverse switch are built into the pedestal, along with a microswitch that currently powers everything down if the top cover is opened, but will eventually interlock with a belt guard. The motor is a salvaged GE 1/4 horse capacitor-run motor, so it is easy to reverse, but it takes a fairly large capacitor. That fills a good chunk of the pedestal and sits in a well routed into the base.

The pedestal is made of scrap 1 inch wide by 2 inch deep extruded architectural aluminum channel, with some smaller chunks of 3/4 by 3/4 inch channel for bracing.

The motor mount is calculated to put 12.5 pounds of weight on the belt, based on a 10 pound motor (I weighed it first, then did the motor mount calculations). That's based on the Gates recommendations for the tension on their series 3M belts -- they suggest a minimum tension per strand of 5 pounds, and a maximum of 7.5 pounds. For two strands (a full loop of belt), that's a total tension of 10 to 15 pounds, so I aimed for the middle.

The motor mount allows the motor to flip inward to make a small package for storage, or to hang out of the way in back to run the lathe. Working out the details of that led me to buy a Gates 3M650 belt. This is actually shorter than the 5M800 belt that came with the lathe when I bought it from E-bay. I have no clue how its original owner mounted it. Perhaps it was a below-the-bench motor mount.

The on-off switch in the base is a pull-on, push-off switch. Inside the base, you can see that it's just a plain toggle switch, with a knob that pushes and pulls the toggle. The knob has hard stops in both directions, so you never put stress on the switch handle no matter how hard you bang the knob to turn off the lathe. There's a grip turned on the aluminum knob for pulling, and the front has a red PVC insert (convention says that pushing a red switch ought to turn things off). I knew that I wanted a red insert, but how to make it? The answer turned out to be polymer clay. I used Sculpy Primo, but I suspect that Fimo or regular Sculpy would work about as well. I turned a tapered hollow in the front of the knob, and then cut grooves into the taper so that when I pressed in the polymer clay, it would lock in place. Then I baked the entire knob to turn the clay into hard PVC. The finish on the front face of the PVC was achieved by pressing the soft clay in place against a sheet of saran wrap against a clean countertop, and then carefully peeling off the saran wrap and blotting up the thin layer of clay that remained on the aluminum edge of the front face.