I appreciate that the stock Taig motor mount works, and is inexpensive, but I decided to try out an idea I've had kicking around in my head for a while. I modified the stock motor mount with a few extra pieces. Total time was about 10 minutes, give or take...ok, maybe more like 20.

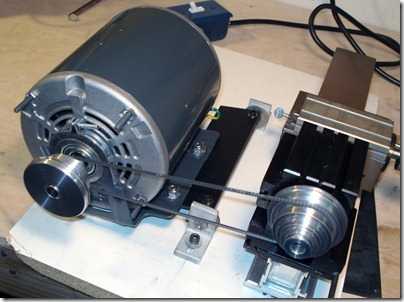

The parts: Stock taig mounting plate, 1/2" steel shaft with two #10-32 tapped holes to mount to the mounting plate, angle brackets made from 1/4" aluminum angle, drilled 1/2" and slotted. misc hardware.

Assembled.

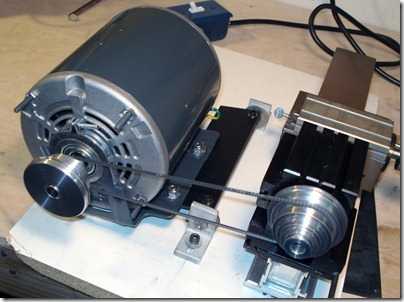

In place. The mounting holes are inline with the predrilled mounting holes (notice the thin pencil line that picked them up). Slots mean you don't have to be precise.

Side view. Works like a charm and is much more rigid.

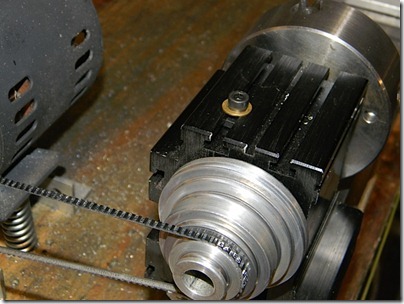

“Turned this from a piece of key stock.”

“Turned this from a piece of key stock.”