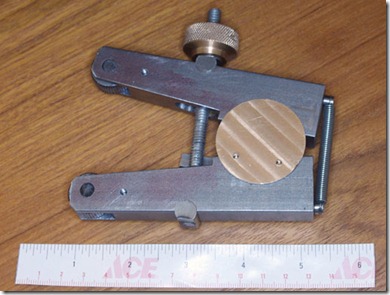

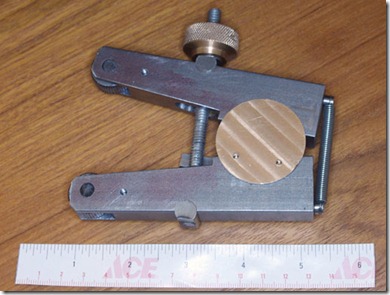

John Silvia sent these pics of a knurling tool made on the Taig lathe and mill:

"I was inspired to make a set of knurling tools based on a picture I saw of an old German knurling tool. The design and construction was heavily influenced by the material and tools that I had on hand. As can be seen in the photos I was experimenting with the exact design and dimensions as I made it. It is somewhat oversized for the taig but I intend to use it someday on a larger lathe with the addition of a second pivot assembly.

Speaking of the pivot assembly, although it looks like brass in the photos, it is made of some bronze I happened to have. The 1/4" bar for the taig tool holder is attached off center to help raise the tightening knob as high as possible to keep fingers well clear when knurling close to the chuck.

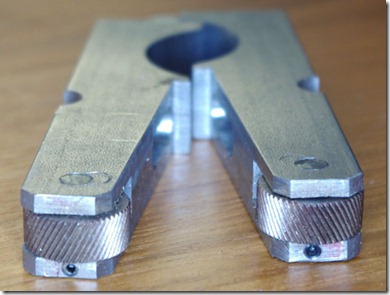

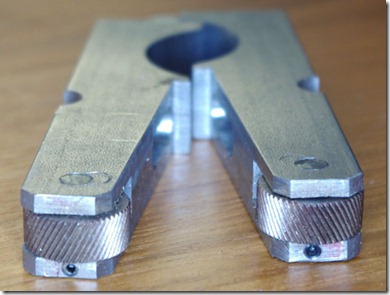

I had planned to hold the knurl pivots in place via set screws; but two sets of knurls that I ordered had shoulders on them that increased their width to the point that there wasn't enough room for set screws, so I had to use a different retaining mechanism made from "hacksaw blades" from the dollar store. This means that more clearance is required on one side when knurling but this really doesn't matter since the arms can be flipped to put the retaining mechanism on either side.

I'm pleased with the results. The first thing I knurled is the knob for the tool itself.

If I were making another one for the taig only, I would make the arms shorter. When I try to knurl a long test piece, a lot of torque is put on the tool holder. It is difficult to get it secured well enough that it doesn't accidentally pivot when advancing the knurler along the knurlee. Shorter arms would probably help reduce the torque. I bought the springs at the local hardware store. They make it slightly more convenient to use but are not necessary.

This is only the second item of any complexity at all that I have machined myself so please be understanding when viewing the pictures. This was very much a learning experience for me."