Clint Says:

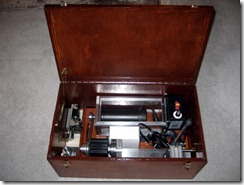

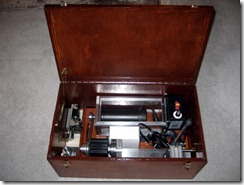

The motor setup is the Penn Industries unit with controller. I have attached one more picture of my setup. I had always wanted a Unimat lathe for the past 40 years, but never could afford one. Started looking on eBay last January and saw the very high prices for used units, so I ended up with the Taig. I made a storage box similar to the Unimat from a surplus high quality cabinet drawer.

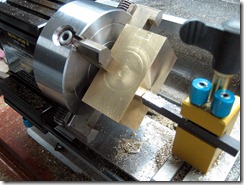

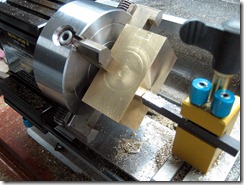

The tool is about 95% finished - not perfect, but very usable. I need to shave off about 3/1000" from one side in order to minimize the run-out as I rotate the block. I have attached some pictures of the unit and my facing setup. I went back and used a different tool for the facing. Was using the standard Taig cutoff tool - about 1/8" wide at the tool end. Used a HF tool that had about 1/4" wide end. You can see the bigger tool in the pictures.

I am getting the hang of making very small incremental advances for each cutting. I need to look at getting a better way to make small movements on the cross-slide that attaches the tool post. Using the cutting tool in the tool post might be better than using the Taig fly cutter. I think that I can work on bigger pieces of flat stock, plus having the cutting tool stationary might be better as opposed to having it rotate on the head stock. You would have a much better idea on this.

This has sure been a good training exercise for me. I still need to get better at using the Taig boring bar. It is really too big to start with small holes and I had trouble with cutting off the first part of the hole while trying to cut off deeper into the hole. I picked up a blank stock and will try to make one that can start with a 1/4" OD hole. BTW - I have some countersink deburring tools coming - using drill bits just does not work too good :-).

![Live center Lrg head[1] Live center Lrg head[1]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEif_GVRWcsuzxoGkGP2kkmb0Mcnw-Yo1XTKRPlEtg4L2BgsfQbIv9cDKH-lao7TOTmUzpvzUZVcqoXwm7yDguty5W0eLAKaW4vNODvnr1fNYmWSMAW2N5NmGun8kjxrxkKNhVimgv6Eqjw/?imgmax=800)